An overview of Stainless Steel Flanges.

Share

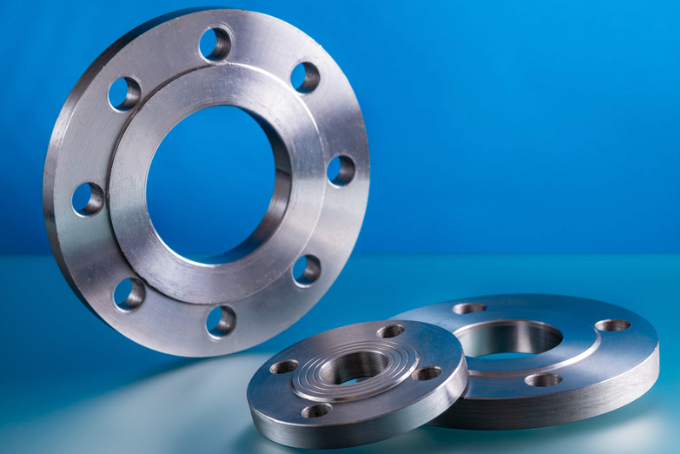

What are Stainless Steel Flanges?

Introduction to Flanges

Stainless steel flanges are essential components used in piping systems to connect pipes, valves, pumps, and other equipment. They provide a reliable way to create a sealed, bolted connection between two sections of a piping system, allowing for easy assembly, disassembly, and maintenance. Flanges are crucial in systems that require frequent inspection or maintenance, as they allow for quick and secure connections without the need for welding.

The use of flanges in piping systems dates back to the development of modern industrial plumbing, where the need for durable and flexible connections became apparent. Over the years, stainless steel has become the material of choice for flanges due to its excellent corrosion resistance, strength, and versatility. Today, stainless steel flanges are widely used across various industries, from oil and gas to pharmaceuticals, where they ensure the safe and efficient operation of critical systems.

Key Characteristics of Stainless Steel Flanges

Durability and Strength

One of the primary reasons stainless steel is favored for flanges is its exceptional durability and strength. Stainless steel flanges can withstand high pressures and temperatures, making them suitable for use in demanding industrial environments. The material’s high tensile strength ensures that the flanges maintain their structural integrity even under heavy loads, providing a secure and leak-proof connection between pipe sections.

The durability of stainless steel flanges also translates to a longer service life, reducing the need for frequent replacements and maintenance. This longevity is particularly valuable in industries where downtime can be costly, such as in oil and gas production or power generation.

Corrosion Resistance

Corrosion resistance is a critical factor in the performance of flanges, especially in environments where the flanges are exposed to harsh chemicals, moisture, or saltwater. Stainless steel flanges are highly resistant to corrosion, thanks to the chromium content in the alloy, which forms a protective oxide layer on the surface of the material.

This corrosion resistance makes stainless steel flanges ideal for use in chemical processing, marine applications, and other environments where other materials might degrade over time. Different grades of stainless steel, such as 304, 316, and duplex, offer varying levels of corrosion resistance, allowing for the selection of the appropriate material based on the specific conditions of the application.

Flexibility and Versatility

Stainless steel flanges are available in a wide range of sizes, pressure ratings, and configurations, making them versatile enough to meet the needs of diverse applications. Whether for high-pressure steam lines in a power plant or sanitary connections in a pharmaceutical facility, there is a stainless steel flange designed to meet the specific requirements of the system.

Additionally, stainless steel flanges can be customized to suit unique applications, with options for different face types (such as raised face, flat face, or ring-type joint) and bolt hole patterns. This flexibility ensures that stainless steel flanges can be seamlessly integrated into existing systems or tailored to meet the demands of new projects.

Ease of Installation and Maintenance

One of the key advantages of stainless steel flanges is their ease of installation and maintenance. The bolted connection provided by flanges allows for quick and secure assembly, without the need for specialized welding equipment or skills. This makes flanges an attractive option in applications where frequent disassembly and reassembly are required, such as in inspection or maintenance routines.

Maintenance is also simplified with stainless steel flanges, as the material's corrosion resistance reduces the likelihood of rust or degradation over time. Should a flange or the connected piping need to be replaced, the bolted connection allows for easy removal and replacement, minimizing downtime and ensuring the continued reliability of the system.

Types of Stainless Steel Flanges

Weld Neck Flanges

Weld neck flanges are designed for high-pressure systems and are easily recognizable by their long, tapered hub, which provides additional reinforcement and distributes stress evenly across the flange. The neck is welded to the pipe, creating a strong and durable connection that can withstand extreme pressures and temperatures.

These flanges are commonly used in oil and gas pipelines, chemical processing plants, and power generation facilities, where the integrity of the connection is critical to the safe operation of the system. The use of weld neck flanges helps ensure that the piping system can handle the demands of high-pressure and high-temperature environments without compromising safety.

Slip-On Flanges

Slip-on flanges are a popular choice for lower-pressure applications, where ease of installation is a priority. These flanges are designed to slide over the pipe and are then welded in place, both on the inside and outside of the flange. This design makes slip-on flanges easier to align and install compared to weld neck flanges, although they offer slightly less strength.

Slip-on flanges are commonly used in systems where the pressure and temperature conditions are less extreme, such as in water treatment facilities, HVAC systems, and low-pressure steam lines. Their cost-effectiveness and ease of installation make them a preferred choice for many applications.

Blind Flanges

Blind flanges are used to seal off the end of a piping system or a vessel, preventing the flow of fluids or gases. Unlike other types of flanges, blind flanges do not have a bore, making them ideal for applications where a secure, leak-proof seal is required. They are often used in pressure testing applications, as they allow for the isolation of a section of the pipeline for testing purposes.

The use of stainless steel blind flanges ensures that the seal remains corrosion-resistant and durable, even in harsh environments. These flanges are widely used in industries such as oil and gas, chemical processing, and water treatment, where the ability to securely close off a pipeline is essential for safe and efficient operation.

Types of Stainless Steel Flanges (Continued)

Socket Weld Flanges

Socket weld flanges are designed for small-diameter, high-pressure piping systems. These flanges feature a socket into which the pipe is inserted before being welded in place. The socket weld design provides a smooth bore and improved flow characteristics, making it suitable for applications where cleanliness and flow efficiency are important.

Socket weld flanges are commonly used in chemical processing, pharmaceuticals, and food processing industries, where the prevention of contamination and the maintenance of high-pressure integrity are crucial. The use of stainless steel ensures that these flanges offer excellent corrosion resistance and durability, even in challenging environments.

Threaded Flanges

Threaded flanges, also known as screwed flanges, are used in systems where welding is not possible or practical. These flanges are designed with internal threads that match the external threads on the pipe, allowing for a secure connection without the need for welding. Threaded flanges are typically used in low-pressure, non-critical applications where ease of installation and disassembly is a priority.

Stainless steel threaded flanges are often used in industries such as plumbing, water treatment, and oil and gas, where quick and easy assembly and disassembly are required. Their corrosion resistance and strength make them a reliable choice for applications where welding is not feasible.

Lap Joint Flanges

Lap joint flanges are used in conjunction with stub ends to create a flexible, removable connection in the piping system. The flange itself is not welded to the pipe but is instead allowed to rotate around the stub end, which is welded to the pipe. This design makes lap joint flanges particularly useful in systems where frequent disassembly is required, as the flange can be easily aligned and connected without the need for precise bolt hole alignment.

Stainless steel lap joint flanges are commonly used in industries such as pharmaceuticals, food processing, and water treatment, where hygienic conditions and ease of maintenance are critical. The corrosion resistance of stainless steel ensures that these flanges remain durable and reliable, even with repeated assembly and disassembly.

Ring Type Joint (RTJ) Flanges

Ring type joint (RTJ) flanges are designed for high-pressure and high-temperature applications, where a leak-proof connection is critical. These flanges feature a groove in which a metal ring gasket is placed, creating a strong seal when the flanges are bolted together. The RTJ design provides excellent sealing capabilities, making it ideal for use in harsh environments.

RTJ flanges are commonly used in the oil and gas industry, particularly in offshore platforms, refineries, and petrochemical plants, where the conditions are extreme, and the integrity of the connection is paramount. Stainless steel RTJ flanges offer superior corrosion resistance, ensuring that the seal remains intact and reliable even in the most demanding environments.

Custom Flanges

In addition to standard types, custom stainless steel flanges can be manufactured to meet specific requirements or unique piping configurations. These custom flanges may include specialized shapes, sizes, or connection types designed to address the challenges of particular applications.

Custom flanges are often used in industries with highly specialized needs, such as aerospace, nuclear power, and advanced manufacturing. The versatility of stainless steel allows for the creation of bespoke solutions that provide the necessary strength, corrosion resistance, and reliability for even the most demanding applications.

Industries That Use Stainless Steel Flanges

Oil and Gas Industry

The oil and gas industry is one of the largest users of stainless steel flanges, particularly in the construction and maintenance of pipelines, refineries, and offshore platforms. The strength, durability, and corrosion resistance of stainless steel flanges make them ideal for use in these harsh environments, where they must withstand high pressures, extreme temperatures, and exposure to corrosive substances such as saltwater and hydrocarbons.

Stainless steel flanges are used in various applications within the oil and gas sector, including wellhead connections, pipeline assemblies, and process piping in refineries. The reliability and safety provided by these flanges are critical to the efficient operation of oil and gas infrastructure.

Chemical Processing

In the chemical processing industry, stainless steel flanges are essential for handling aggressive chemicals and corrosive substances. The resistance of stainless steel to a wide range of chemicals, including acids, bases, and solvents, makes it the material of choice for pipelines, reactors, and storage tanks.

Flanges in this industry are used to ensure leak-proof connections in systems that transport hazardous materials. The seamless connections provided by stainless steel flanges reduce the risk of leaks and contamination, which is crucial in maintaining safety and operational efficiency in chemical plants.

Water Treatment and Distribution

The water treatment and distribution industry relies on stainless steel flanges for the construction and maintenance of pipelines that transport water, chemicals, and other fluids. The material's resistance to corrosion, especially in environments where exposure to chlorine or other disinfectants is common, makes stainless steel flanges an ideal choice for these applications.

Stainless steel flanges are used in municipal water treatment facilities, desalination plants, and industrial water systems, where they help ensure the reliability and safety of water distribution networks. Their durability and resistance to environmental factors ensure that these flanges provide long-term performance with minimal maintenance requirements.

Importance of Stainless Steel Flanges in Modern Industries

Structural Integrity

Stainless steel flanges play a crucial role in maintaining the structural integrity of piping systems. The bolted connection provided by flanges ensures a secure and leak-proof joint, which is essential in industries where the failure of a connection could lead to costly downtime or dangerous situations. By providing a robust and reliable connection, stainless steel flanges help ensure the overall stability and safety of the piping system.

The strength and durability of stainless steel flanges also contribute to the longevity of the piping system, reducing the need for frequent replacements and maintenance. This structural integrity is particularly important in high-pressure and high-temperature applications, where the performance of the flanges is critical to the safe operation of the system.

Efficiency and Flow Optimization

The design of stainless steel flanges allows for efficient flow dynamics within the piping system. The smooth bore provided by these flanges minimizes turbulence and pressure drops, ensuring that fluids and gases can flow freely through the system without obstruction. This efficiency is crucial in industries where maintaining consistent flow rates is essential, such as in chemical processing, water treatment, and HVAC systems.

By optimizing flow, stainless steel flanges help improve the overall efficiency of the system, reducing energy consumption and operational costs. The precision machining and quality control used in the manufacturing of stainless steel flanges ensure that they meet the exacting standards required for optimal flow performance.

Cost-Effectiveness

While stainless steel flanges may have a higher initial cost compared to other materials, their long-term benefits make them a cost-effective choice for many applications. The durability and corrosion resistance of stainless steel reduce the need for frequent maintenance and replacements, leading to lower lifecycle costs. In industries where downtime can be costly, the reliability of stainless steel flanges helps minimize disruptions and extend the service life of the piping system.

The ease of installation and maintenance provided by stainless steel flanges also contributes to their cost-effectiveness. The bolted connections allow for quick and easy assembly, reducing labor costs and minimizing downtime during installation or maintenance procedures. These advantages make stainless steel flanges a wise investment for a wide range of industrial applications.

Governing Standards and Third-Party Agencies

Overview of Governing Standards

To ensure the quality, safety, and performance of stainless steel flanges, various governing standards have been established by international organizations. These standards define the specifications for material composition, dimensions, pressure ratings, and testing methods. Adhering to these standards ensures that stainless steel flanges meet the required criteria for their intended applications.

Key standards organizations include ASTM International (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), and ISO (International Organization for Standardization). Compliance with these standards is essential for maintaining the reliability and safety of stainless steel flanges in critical applications.

Role of Third-Party Agencies

Third-party agencies play a vital role in certifying that stainless steel flanges comply with relevant standards and specifications. These agencies conduct independent testing and inspections to verify that the flanges meet the required quality and performance criteria.

For example, ASTM International provides certification based on rigorous testing protocols, ensuring that stainless steel flanges meet industry standards for strength, durability, and corrosion resistance. ISO certifications are also widely recognized and respected, providing assurance that the flanges are manufactured to the highest quality standards.

The involvement of third-party agencies adds an extra layer of assurance for industries that rely on stainless steel flanges, ensuring that the products they use are safe, reliable, and fit for purpose.

Impact of Compliance on Quality and Safety

Compliance with governing standards and third-party certifications directly impacts the quality and safety of stainless steel flanges. Adherence to these standards ensures that the flanges possess the necessary mechanical properties, corrosion resistance, and durability to perform effectively in their intended applications.

In industries where safety and reliability are critical, such as oil and gas, chemical processing, and pharmaceuticals, compliance with these standards helps prevent accidents, leaks, and system failures. It also ensures that manufacturers maintain consistent product quality, reducing the risk of defects and ensuring customer satisfaction.

Examples of Specific Standards

Two key standards that govern the specifications for stainless steel flanges are ASTM A182 and ASME B16.5. ASTM A182 covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves, specifying the requirements for chemical composition, mechanical properties, and testing methods. This standard is crucial for ensuring the quality and performance of flanges used in high-pressure and high-temperature environments.

ASME B16.5 provides guidelines for pipe flanges and flanged fittings in sizes NPS ½ through NPS 24. It includes specifications for dimensions, pressure ratings, materials, and testing methods. Compliance with ASME B16.5 ensures that stainless steel flanges are suitable for use in a wide range of industrial applications, from power generation to chemical processing. Together, these standards help guarantee that stainless steel flanges meet the rigorous demands of modern industry.

Case Study: Industry Compliance

A notable example of industry compliance with stainless steel flange standards can be seen in the construction of a large-scale offshore oil platform. The platform required robust and corrosion-resistant flanges to connect various sections of the piping system exposed to harsh marine environments. By adhering to ASTM A182 and ASME B16.5 standards, the engineering team ensured that all flanges used on the platform met the necessary quality and performance criteria.

Third-party certification from ISO provided additional assurance that the flanges would perform reliably under the platform's demanding conditions. This compliance helped the platform achieve safe, efficient operation, minimizing the risk of leaks, corrosion, and system failures.

Choosing the Right Stainless Steel Flange for Your Industry

Factors to Consider

Selecting the appropriate stainless steel flange for your industry involves considering several factors, including the material grade, size, pressure rating, and intended use of the flange. The choice between 304 and 316 stainless steel, for example, will depend on the corrosive environment and temperature conditions the flange will be exposed to.

Other factors include the pressure and temperature ratings of the flange, which must match the operating conditions of the piping system. It's also important to consider the compatibility of the flange with the type of fluid or gas being transported, as well as the need for compliance with industry standards and third-party certifications.

Consulting with Experts

Consulting with industry experts or manufacturers who specialize in stainless steel flanges can be invaluable when choosing the right flange for your project. Experts can help assess the specific needs of your application, recommend the most suitable grades and specifications, and ensure that the selected flanges comply with relevant standards and certifications.

For custom or highly specialized applications, expert consultation can also assist in designing custom flanges that meet the unique challenges of your project. This ensures that the final product is not only reliable and efficient but also fully compliant with industry standards.

Third-Party Certifications

When selecting stainless steel flanges, it’s important to ensure that the products come with third-party certifications from recognized agencies like ASTM or ISO. These certifications confirm that the flanges meet the required standards for quality, safety, and performance, providing peace of mind that they have undergone rigorous testing and inspection.

In industries where safety and reliability are paramount, such as pharmaceuticals, chemical processing, and oil and gas, third-party certifications are often mandatory. Verifying that your stainless steel flanges come with the necessary certifications helps ensure that your piping system will perform reliably and safely in its intended application.

Conclusion

Recap of Key Points

Stainless steel flanges are essential components in a wide range of industries, offering secure, durable, and corrosion-resistant connections that enhance the performance and reliability of piping systems. Their use in industries such as oil and gas, chemical processing, and water treatment underscores their importance in maintaining safe and efficient operations.

Compliance with governing standards, such as those set by ASTM, ASME, and ISO, is critical for ensuring the quality and safety of these flanges. Third-party certifications provide additional assurance that the flanges meet the highest standards of performance and reliability, making them a trusted choice for critical applications.

Final Thoughts

As industries continue to evolve and demand higher performance from their materials, stainless steel flanges will remain an essential component in ensuring the efficiency, safety, and sustainability of various operations. Whether for structural, hygienic, or high-pressure applications, these flanges offer a combination of strength, durability, and corrosion resistance that is unmatched by other materials.

Incorporating authoritative references and maintaining compliance with industry standards will continue to be critical for manufacturers and users alike. As technological advancements and innovations in stainless steel continue to emerge, the future looks promising for this versatile and indispensable material.

To further enhance your understanding of stainless steel flanges, it’s essential to consult authoritative sources. Key resources include ASTM International, which provides detailed specifications and guidelines for stainless steel flanges, and the American Society of Mechanical Engineers (ASME), which offers standards for dimensions and pressure ratings.

FAQs About Stainless Steel Flanges

1. What are the most common types of stainless steel flanges?

The most common types of stainless steel flanges include weld neck flanges, slip-on flanges, blind flanges, socket weld flanges, threaded flanges, lap joint flanges, and ring type joint (RTJ) flanges. Each type serves specific purposes, such as handling high-pressure environments, providing ease of installation, or allowing for frequent disassembly.

2. How do I choose the right stainless steel flange for my application?

Choosing the right stainless steel flange involves considering factors such as the material grade (e.g., 304 or 316 stainless steel), the pressure and temperature ratings, the type of fluid or gas being transported, and the specific requirements of your application. Consulting with industry experts can help ensure that the selected flange meets the necessary standards and performs reliably in your intended environment.

3. Why is corrosion resistance important for stainless steel flanges?

Corrosion resistance is crucial for stainless steel flanges because it ensures the longevity and reliability of the piping system, especially in environments exposed to harsh chemicals, moisture, or saltwater. Stainless steel's resistance to corrosion helps prevent leaks, structural failures, and the need for frequent maintenance, making it a preferred choice in industries like oil and gas, chemical processing, and marine applications.

4. Are there industry standards that stainless steel flanges must comply with?

Yes, stainless steel flanges must comply with various industry standards, such as ASTM A182 and ASME B16.5. These standards specify the requirements for material composition, dimensions, pressure ratings, and testing methods, ensuring that the flanges meet the necessary criteria for quality and safety. Compliance with these standards is essential for reliable performance in critical applications.

5. What maintenance is required for stainless steel flanges?

Stainless steel flanges require minimal maintenance due